September 17, 2024

Engineering source and S3000L Product Support Analysis (PSA) data provide a basis for S2000M Provisioning Projects. Using S3000L Breakdown and Task Resource data help organize and structure S2000M Provisioning Projects. This also enables data interoperability between Engineering, Support Analysis and Material Support.

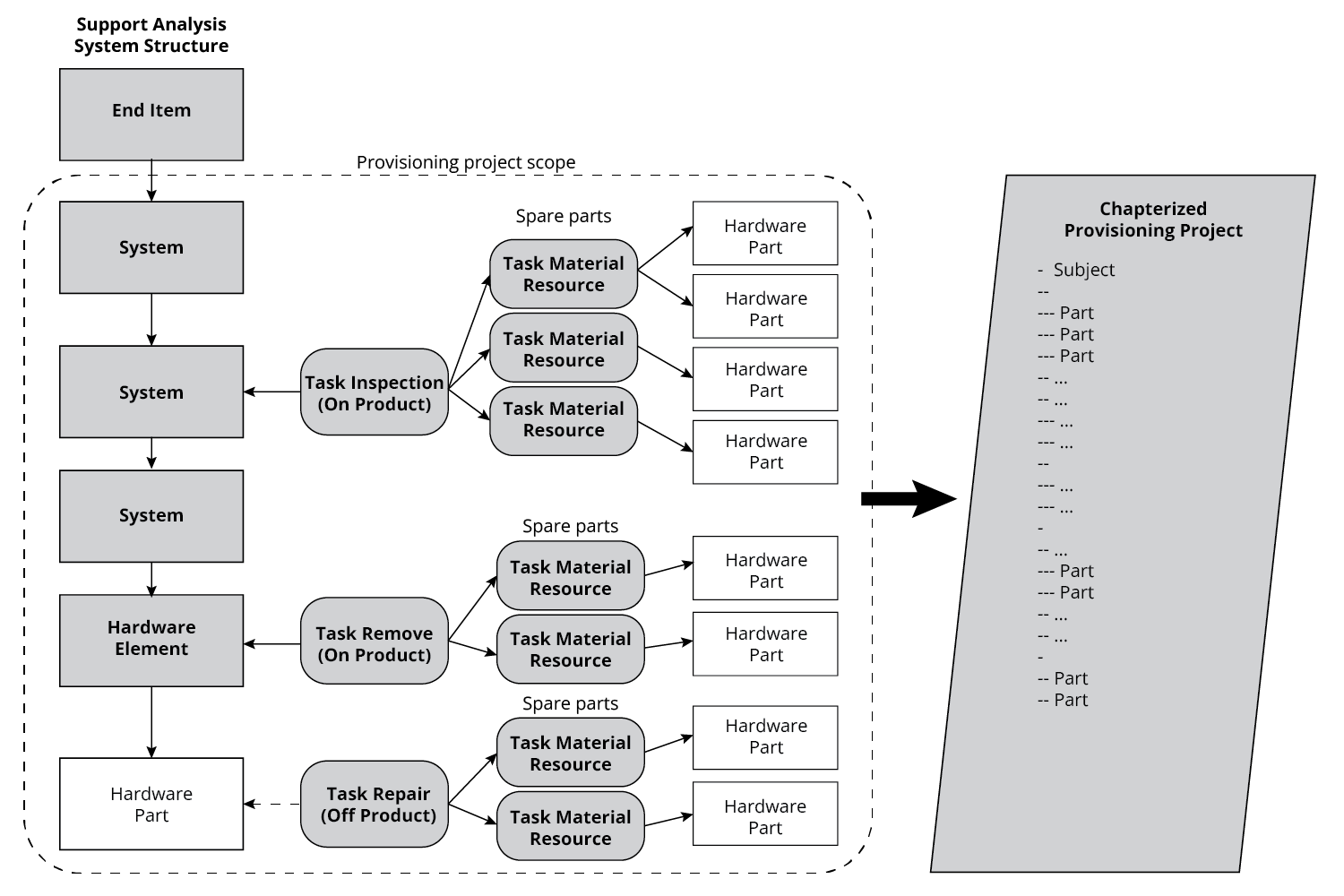

The starting point for organizing product structures for support analysis activities begins with the S3000L engineering system breakdown. It also examines the physical definition, including the Bill of Material (BOM) part information for major equipment.

An outcome of support analysis is the Support Bill of Materials (SBOM). The SBOM lists only parts consumed during operation and maintenance of the Product. Decisions made when performing task analysis can determine parts that can be replaced by other part numbered items such as pre-assembled spare parts.

Information generated during the PSA process determines the range and depth of the maintenance of the Product. This includes required material resources during in-service operation. The result is a support-oriented system breakdown. In many cases a one-to-one relationship is established with the engineering breakdown.

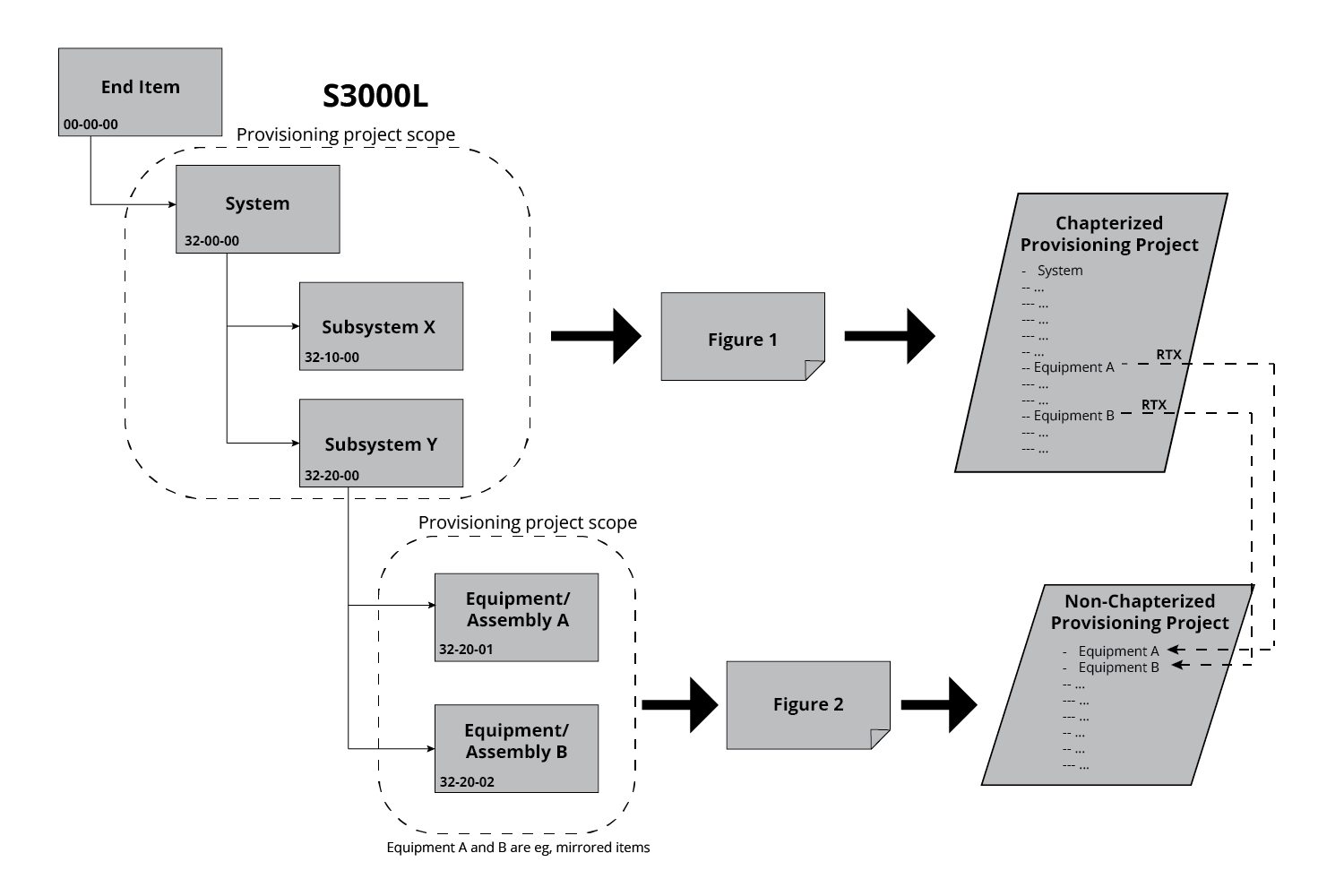

The system breakdown structure can be broken down into a set of chapterized provisioning projects. These provisioning projects can be based on systems and subsystems depicted by figures and illustrations for the system from a provisioner or maintainer perspective. This is a decision to be made by the provisioner.

The next step analyzes details for breakdown element realizations in S3000L where parts are identified via HardwareElementRealization. Details for the part Bill of Material can be documented as part of the provisioning project for the system where a part is unique to the system managed by the provisioning project. This could lead to the inclusion of an additional figure illustrating the assembly for the part.

Parts which share most of the physical breakdown can be documented as different figure item realizations (ISN) under the same figure item (CSN). This includes different configurations, mirrored items, and reworked items.

Candidates for grouping parts that share most of the physical breakdown can be identified through S3000L hardware element realizations, alternate parts, substitute parts, and through hardware elements with similar SNS’s.

The SBOM will initially reflect only parts which are needed for maintenance of the equipment/assembly. However, the final content of a provisioning project must also consider repair kits and part kits. Pre-assembled spare parts, repair kits and/or part kits can also be incorporated into the SBOM.

The starting point for identifying provisioning spare parts is the equipment/assembly Support Bill of Material’s (SBOM) resulting from the S3000L analysis. The breakdown for the part (equipment/assembly) can start at indenture level directly below the assembly.

It is recommended to identify task material resources classified as spare parts through S3000L. Alternate parts and substitute parts in S3000L will appear as individual ISN’s in the provisioning project.

There is also the case where an equipment/assembly regarded as a spare task material resource in the PSA will be supplied in parts. This can result in the need to document additional tasks and subtasks in the PSA describing actions needed to assemble the equipment/assembly.

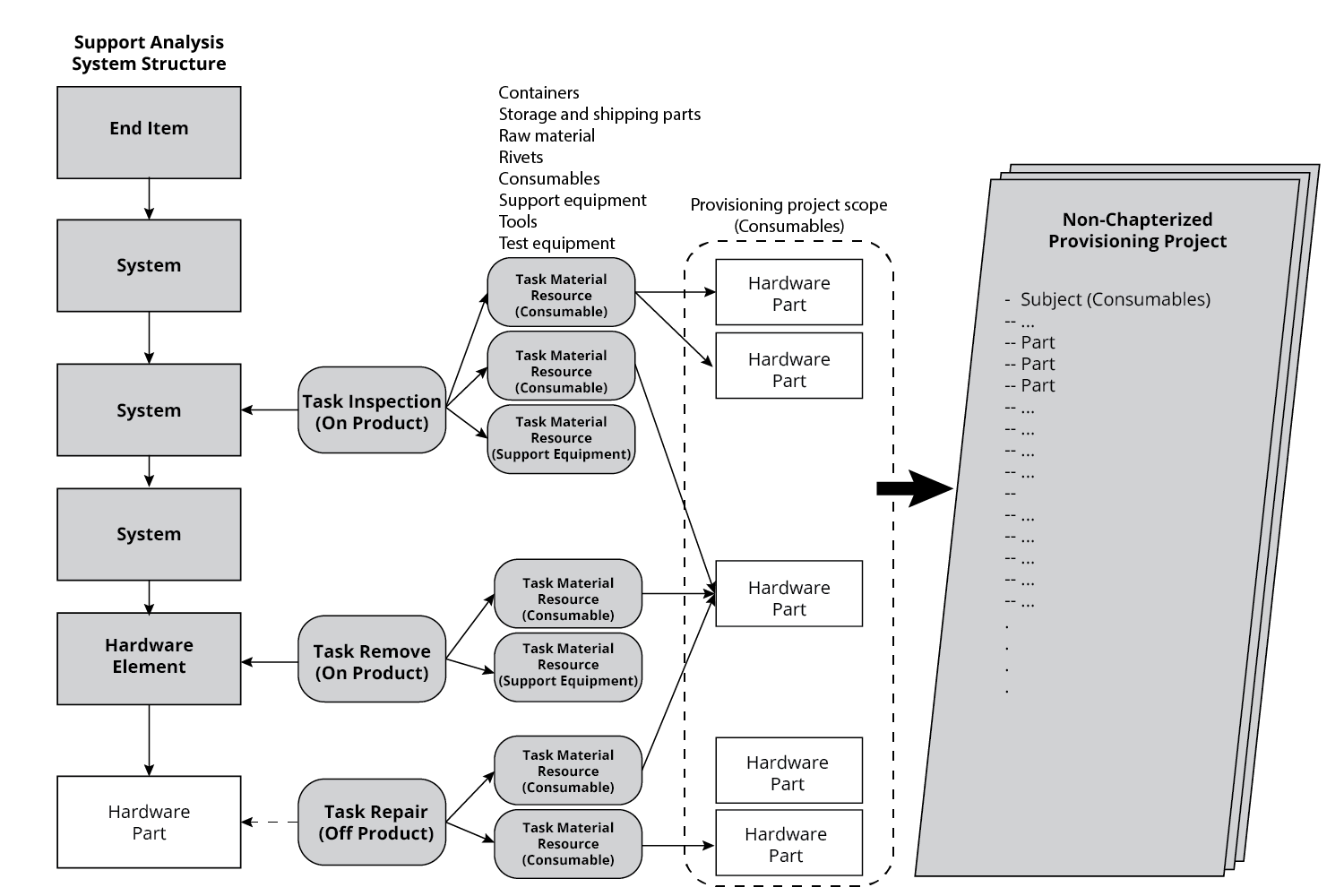

It is recommended to identify additional resources that need to be provisioned to support the system(s) and parts (equipment/assemblies) in scope for the provisioning project. The starting point for this analysis identifies relevant tasks (both On-Product and Off-Product) that require task resources in terms of consumables, support equipment, containers, and so on. The provisioning activity must ensure that all task material resources required to perform the identified tasks are included in the provisioning projects.

In the same way as for any part installed on the end item, there must be a decision on whether the identified task material resources require their own provisioning project similar to major equipment/assemblies.

Engineering source and S3000L Product Support Analysis data should provide a basis for S2000M Provisioning Projects from a data element and data process perspective. This can organize and structure S2000M Provisioning Project data, as well as enable data interoperability between Engineering, Support Analysis, and Material Support.

This alignment of data and process is also applicable to other S Series functional areas. This includes Technical Documentation (S1000D) and training Analysis and Design (S6000T). The steps described can provide a synchronized set of Product Support data and deliverables.

The terminology of chapterized and non-chapterized provisioning project originates from early versions of the S1000D Standard Numbering System (SNS).

Chapterized provisioning projects are based on the system breakdown of the Product. A chapterized provisioning project is organized into a set of figure items (identified by Catalogue Sequence Number, CSN) which reflect find numbers in the respective illustration. Figure items can be organized in structures using indenture level codes, within the figure.

Non-chapterized provisioning projects are primarily based on the assembly structure (Bill-of-Material) for equipment/assemblies. Non-chapterized provisioning projects represent equipment/assemblies independent from their usage in the Product.